For me, 2021 was much easier than 2020 so at least the year had that going. I was a little overambitious setting my goals for the last year, something I will address below. As for my word of the year, recovery, I pretty much nailed it. I kept my health at the forefront throughout the year and while things didn't always go as planned, I did go into remission after having the surgery I was trying to avoid. I have been active in dealing with my anxiety and depression, and I have a team of amazing doctors who listen to me and work with me to find solutions that work for me instead of treating me like a checklist. All of this resulted in a stronger me at the end of the year which in and of itself feels like a complete success.

Now for the evaluation of my yearly goals for 2021

2021 by the numbers

- Read 40 books I think I did this, I reread a bunch of books and didn't do a great job of keeping up with everything.

- Knit 12 projects Yes!- While I haven't added most of them to my Ravelry projects page, I think the final count was 27.

- Add 100 squares to my Memories Blanket Nope- Again I lost count, but I think I ended up adding around 50.

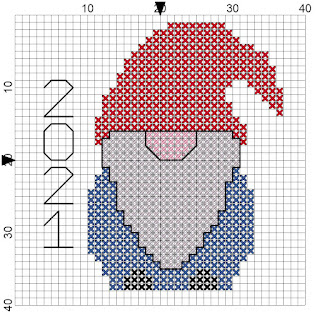

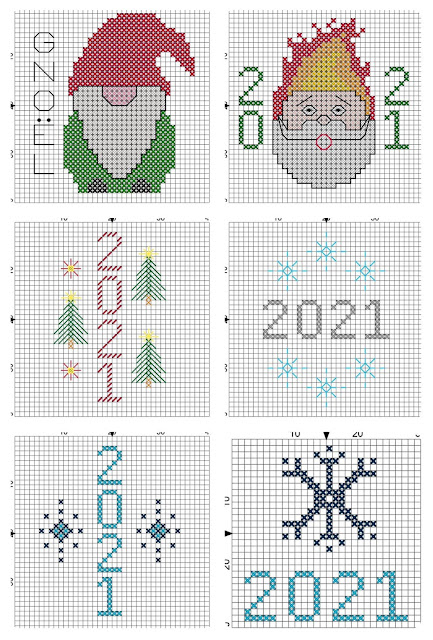

- Design 8 new cross stitches Three, I designed three. This was one of the ways I wasn't feeling super creative this year and honestly I am glad I didn't push myself to do things that don't make me happy just to achieve a number. I am very proud of all three of the designs I made and that will just have to do.

- Write 12 blog posts HAHAHAHA!! Okay, let's face if, my dream of bringing this blog back to regular entries might be just that, a dream. I will keep it up and use it as a place to host my occasional free pattern and my yearly goals, but that might be all it will be going forward. That is okay, I loved my years of regular blogging and documenting my life, but also I was more open to sharing then. I tend to be more private these days and again, that is okay.

- Play 50 new board games I achieved this goal somewhere around the middle of the year. I love playing games and I love trying new games so this was mostly effortless. Thanks to vaccines, I was able to play games in person with close friends several times this year which was also amazing.

- Walk 600 miles Another goal that I stopped tracking early in the year, but since I was at the halfway point around April, I think it is safe to say I crushed it. Walking is such an important part of my life, it helps lower my stress, it gives me quiet time to process my day, it jump starts my creativity, it keeps my dog happy, and it is just nice to spend some time in nature. I think I set this goal because I wasn't able to walk as much when I was really sick and I could feel it making things worse for me. As my health improved, it wasn't something I had to make an effort to do, just something I did.

- Attend 12 digital classes/lectures What?!! Another thing I lost track of!?! Maybe quantifying everything isn't the best way for me to track my progress. I am so numerically focused, but also I hate doing the actual tracking if I don't have a good system for it. Anyway, I am not sure I did 12, but I think I probably did 8-10 so not bad for a year with a lot of interuptions.

Things to do in 2021

- learn 4 harness weaving Nope, I got overwhelmed, decided to circle back and haven't done that yet. It should also be noted that the loom is in the room with my mom's ashes and I am having trouble actually spending time in there. Hopefully her memorial and burial in April with solve this.

- sew a fitted garment- the Jiffy Popover Dress I thought I wanted to sew in 2021, turns out I didn't.

- sew an intermediate garment- Burnside Bibs See above.

- find and implement daily practices that reduce stress Yes!! I really worked on this in 2021. I started the year with structured creative tasks like latch hook, paint-by-numbers, and macrame (yes, 2021 was a big year for 1970's crafts) and ended the year with more freeform creative activities like art challenges. I participated in Inktober for the first year ever and saw a big improvement in my drawing skills, then I participated in a block carving challenge for November that used some of my drawings and reignited my love for printmaking. I didn't do a challenge for December, but I continued trying new printmaking techniques between work shifts.

- make my year as bright and colorful as possible Yes!! I made the effort to incorporate more color into my daily surroundings, I believe this did positive things for my mood and overall outlook on life.

- take a vacation Another yes!! Not only did I take a vacation proper, but I also started planning mini break trips once a quarter. I spent a lot of time in the woods this year and believe that time really aided in my recovery.

Things to quit in 2021

- doom scrolling social media This is a bad habit I still have trouble breaking. I have, however, taken to scrolling art and creative feeds instead of news and other drama so it feels a little healthier.

- negative self talk This is a thing that is so ingrained in my being that I am not sure I will ever actually break it. That said, I have been trying to do more positive self talk and focus on the things I am doing well and things I am thankful for.

- procrastinating simple tasks Looking at my weekly planner spreads for 2021 and the number of 5 minute tasks I rolled over week to week, I think it is safe to say I did not do this. Not sure what the answer is here, the shame of having to add them to every new to do list isn't enough to motivate me, oh well.

Shew, that was a lot. despite not meeting a bunch of hefty goals, I am very happy with my progress in 2021 and would like to continue on the same path for 2022. My word for 2022 is flow, I want to bend to the world while continuing to move forward. My progress won't be a straight line, but that is okay, instead of wasting energy steering myself in the direction I think I am supposed to go, I want to focus my energy on thriving on my path and always moving forward, even if that forward has a lot of twists and turns. I am happy where I am right now, I love myself and the people I have surrounded myself with, I want more of this life.

Goals for 2022- I am keeping them short, simple, and slightly abstract...

- Continue doing things that fuel my creativity. Find ways to explore mediums and techniques outside of my comfort zone and don't be afraid of failure.

- Try to stop quantifying everything. Read, listen to new music, play games, learn new things, wander, and create freely.

- Work on a new secret art project, I miss doing these and I think the world can use a little extra magic right now.

- Start journaling again. Not sure what this looks like, probably not blog entries, but maybe a physical journal. Doesn't need to be rigorous, just a place to document aspects of my life.

.jpg)